The Metal Casting Congress will be held downtown Milwaukee April 25th, 26th and 27th. We would like to invite any representatives from foundries that will be in the area to stop in and tour our facility. Please come and see what Supreme Cores can do to help with your core making needs.

ISO Certification Audit

Supreme Cores recently had their last surveillance ISO audit under the 2008 standard and passed without any non-conformance’s. Over the next year we will be transitioning to the 2015 standard. We are anxious to implement these changes to see our system improve and thrive. As always we are focused on quality products and customer satisfaction. There are great things to come from Supreme Cores.

AFS Northeast Chapter Supplier Night 11/7/16

COME VISIT OUR BOOTH AT THE AFS NORTHEAST CHAPTER SUPPLIER NIGHT. THE EXHIBITION WILL BE OPEN FROM 5:00 PM TO 8:30 PM ON MONDAY NOVEMBER 7TH, LOCATED AT THE BRIDGEWOOD RESORT AND CONFERENCE CENTER IN NEENAH, WI. WE LOOK FORWARD TO SEEING EXISTING CUSTOMERS, MEETING NEW CUSTOMERS AND SPEAKING WITH OTHERS FROM THE FOUNDRY INDUSTRY.

The “Core” News from Supreme Cores

Supreme Cores, Inc. has been working hard to continually improve its efforts as a supplier of cores and molds to the Foundry Industry. I have a couple of items that I want to bring to your attention.

1. We are currently testing alternative Shell sands that will help reduce the formaldehyde levels for the workers at Supreme. The new sands will also be beneficial for our customers who will experience less off gassing during shake out. We are working with our Shell sand suppliers to reduce formaldehyde yet retain many of the same characteristics of the original sands. Resin levels, hot and cold tensile are all very similar to the previous sands. If you are concerned about potential issues with your cores, please let us know and we will work with you to provide sample cores and more information about the new sands.

2. Recently our # 1 customer for the past 2 years dramatically reduced their orders to us. This work was in our Airset ( Pepset ) Department and required about 12 – 16 workers each day. We now have an excess of workers available. We have 3 different mixers available 2 shifts a day in Pepset. Let us know if we can help you with your air set molds or large cores.

3. We are nearly complete with the installation of a new CB-22 machine that will be able to blow Isocure cores. This will be our second machine that can make Isocure cores. The other machine is our Laempe L10. Isocure sand is cheaper per pound than Isoset . Let us know if you have a job you would like for us to blow on this machine.

We hope you have a wonderful Holiday season and a prosperous end to 2015.

Michele Aupli

Human Resources and Operations Manager

michelea@supremecores.com

Margie Broker

Inside Accounting, AP/AR and Scheduling

margieb@supremecores.com

Grey Pope

Quality Department, ISO Manager and in-house Sales/Quoting

greyp@supremecores.com

Ken Strehl

Sales Representative

kens@supremecores.com

Bonnie Oleszek

Receptionist and Trucking Coordinator

bonnieo@supremecores.com

Paul Grossmann

Sales, Customer Service and commitment

paulg@supremecores.com

We appreciate your business, and look forward to serving your core/mold needs in the future. Contact us and let us know how we can serve your foundry today.

Sincerely,

Paul Grossmann

President

Supreme Cores, Inc.

ISO 9001:2008 Re-certification

In the month of May Supreme Cores was due for its ISO 9001:2008 re-certification. After 3 days of audits, Supreme Cores was issued zero corrective actions and was recommended for re-certification. The new certification can be found on the website or you can contact us for a copy.

We, at Supreme Cores, are always looking to improve in order to supply our customers with top quality cores and great service.

Current Lead Times As Of 5/26/15

Below are the current lead-times at Supreme Cores by department and machine.

Add an extra 3 days to each lead-time listed for finishing and packing of the core.

Please contact us for quotes or questions.

Shell Department

– Dependable 400: 1 Week

– Redford 16’s: 1 week – 1.5 weeks

– Redford 22’s: 1 week

– Redford 43’s: 2 Days – 1 Week

– U-180: 1 Week

Warmbox:

– 2 Days – 1 Week

SO2 Department

– Bench: 2 Days – 1 Week

– Gaylords: 2 Days – 1 Week

– Redford 22’s and 16’s: 5 – 8 business days

ISOCURE: 5 – 8 business days

AIREST: 5 – 8 days – depends on team size for the job

77th Annual Wisconsin Regional Foundry Conference

The 77th Annual Wisconsin Regional Foundry Conference will be held at the Crown Plaza in Milwaukee, WI from February 11-13th. A few Supreme Cores employees will be attending the conference on Thursday, February 12th. During their time there they will be meeting with customers, suppliers and other companies that contribute to the foundry industry. The conference also holds technical sessions that inform industry colleagues of important topics. These sessions tend to share knowledge with others in the industry in order to grow and prosper as a whole.

We look forward to seeing new and familiar faces at the conference.

Supreme Cores, Inc.

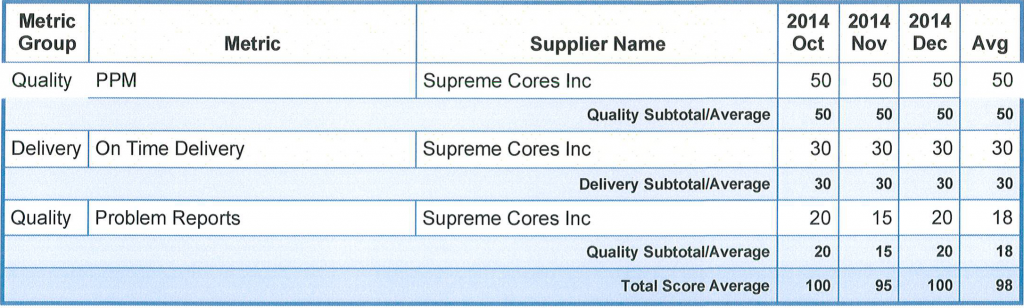

Supreme Cores – A Top Tier Supplier

As the fourth quarter came to a close, Supreme Cores again proves to be a top tier supplier. Our customer scorecards keep arriving with great numbers and positive feedback. With our outstanding quality and always improving on-time delivery, we look forward to providing our customers with a “Supreme” product in 2015.

Supreme Cores Updates Airset Department

Recently our Airset department was updated with new equipment in order to run more efficiently and reduce our scrap. We added a Tinker Omega TOM250 which is capable of mixing 250# of sand per minute. This continuous mixer is identical to our TOM125 but produces more mixed sand per minute. We decided to purchase another Tinker Omega mixer because of the success we had with the TOM125. We have been able to lower our scrap, have faster change overs and keep our LOI’s consistent. We currently have three mixers in our Airset Department in order to keep up with demand and be responsive to customer’s needs. The third mixer has the ability to use specialty sand such as chromite or 80 GFN. This mixer runs off of palletainers or sand and not our pneumatic system as the other two mixers do.

Along with the addition of a mixer we have added an automatic, belt driven conveyor and mold dryer. The conveyor helps by moving the molds down the line without the need of a person’s attention. The speed of the conveyor can be set to keep the mold under the dryer for a specified amount of time. This will keep the mold from overheating and warping. The mold dryer has infrared lights so it directs the heat to the surface of the mold. The heat will then evaporate the water from the core wash leaving a smooth surface.

These new additions have helped us with our throughput and repeatability. They have also helped open capacity in this department to meet our current and future customer needs.

Looking To Fill 2nd Shift Positions

Supreme Cores is currently looking to hire for second shift core making positions. Working hours are from 3:30 pm to 12:00 pm. Applications can be filled out on-site or printed from our website. Click here to print from the website.